Stainless steel threaded rods are widely used in construction, industrial, marine, and automotive applications due to their strength, versatility, and resistance to corrosion. Corrosion resistance is one of the key reasons these rods are chosen over ordinary steel or other materials. However, the level of corrosion resistance depends on material grade, environment, and maintenance practices. This article explores the corrosion-resistant properties of stainless steel threaded rods and how to maximize their longevity in various conditions.

1. Understanding Stainless Steel Corrosion Resistance

Stainless steel is an alloy of iron with chromium, nickel, and sometimes molybdenum. Chromium, typically present at 10–30%, forms a thin, invisible oxide layer on the surface, known as the passive layer. This layer acts as a protective barrier that prevents further oxidation, giving stainless steel its characteristic corrosion resistance.

For threaded rods, this means:

Resistance to rust in humid or wet environments.

Ability to withstand exposure to mild acids and alkaline substances.

Enhanced durability compared to carbon steel threaded rods.

The integrity of this passive layer is critical for maintaining corrosion resistance over time.

2. Material Grades and Their Impact

Not all stainless steel threaded rods offer the same level of corrosion resistance. Common grades include:

304 Stainless Steel: Offers good resistance to oxidation and general corrosion, suitable for indoor and mild outdoor environments.

316 Stainless Steel: Contains molybdenum, which enhances resistance to chlorides and marine environments. Ideal for coastal applications or exposure to saltwater.

410 Stainless Steel: Provides moderate corrosion resistance but is more suited for mechanical strength applications than harsh environments.

Choosing the right grade based on the application is essential to ensure long-term performance.

3. Environmental Factors

The corrosion resistance of stainless steel threaded rods is also influenced by the environment in which they are used:

Indoor use: Typically experiences minimal corrosion due to controlled humidity and absence of aggressive chemicals.

Outdoor exposure: Stainless steel can resist corrosion from rain and moderate humidity but may require higher grades like 316 in coastal or industrial areas.

Marine environments: Saltwater and chloride ions are highly aggressive, making 316 or higher corrosion-resistant grades necessary.

Chemical exposure: Acids, alkalis, and cleaning agents can attack lower-grade stainless steel, necessitating proper grade selection and protective measures.

Environmental awareness is key to selecting the most suitable rod for long-term durability.

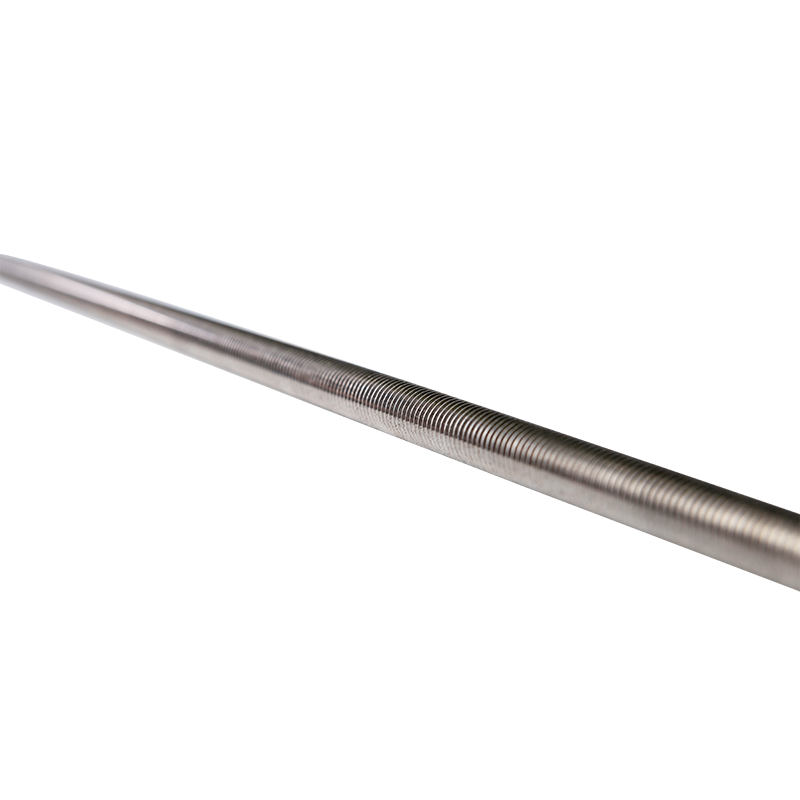

4. Threaded Surface Considerations

The threaded profile of rods introduces micro-crevices, which can be potential points for localized corrosion, known as crevice corrosion. Factors affecting corrosion on threaded surfaces include:

Surface finish: Smooth, polished rods reduce the likelihood of corrosion compared to rough or uneven threads.

Debris and contaminants: Dirt, salts, or chemicals trapped in threads can accelerate corrosion.

Coatings or passivation: Additional treatments can enhance corrosion resistance and protect threads during storage and installation.

Proper handling and surface care are essential to maintain corrosion resistance in threaded rods.

5. Maintenance Practices for Long-Term Resistance

Even though stainless steel is inherently corrosion-resistant, proper maintenance can significantly extend its service life:

Regular cleaning: Remove dirt, dust, and salt deposits using mild detergents or water.

Avoid harsh chemicals: Strong acids or chlorides can damage the passive layer.

Inspection: Periodically check for signs of pitting or localized corrosion, especially in marine or industrial environments.

Lubrication during installation: Using anti-seize compounds can reduce friction and prevent crevice corrosion at threaded connections.

Good maintenance practices help preserve the protective oxide layer and prevent premature corrosion.

6. Applications Benefiting from Corrosion Resistance

Stainless steel threaded rods are used in applications where strength and corrosion resistance are both critical, such as:

Construction: Structural assemblies exposed to rain or humidity.

Marine installations: Boat fittings, docks, and offshore platforms.

Chemical plants: Equipment exposed to mild acids or alkaline solutions.

Automotive and machinery: Components subjected to moisture, oils, or salts.

In these applications, corrosion resistance ensures safety, longevity, and reduced maintenance costs.

Conclusion

Stainless steel threaded rods are highly corrosion-resistant due to the chromium-based passive layer and alloy composition. Their performance varies based on stainless steel grade, environmental conditions, and maintenance practices. 304 stainless steel is suitable for general use, while 316 stainless steel is preferred in aggressive or marine environments.

Although corrosion resistance is a key advantage, proper installation, surface care, and periodic maintenance are crucial to maximize the lifespan of threaded rods. When chosen and maintained correctly, stainless steel threaded rods provide long-lasting durability, reduced risk of rust, and reliable performance across a wide range of applications.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)