Introduction

In the world of mechanical fastening, small components often play a disproportionately large role in ensuring structural integrity and long-term performance. Among these essential parts, stainless steel flat washers stand out as versatile, durable, and indispensable elements across industries. Whether you're assembling furniture at home or constructing industrial machinery, understanding what stainless steel flat washers are, how they function, and why they matter can make a significant difference in the outcome of your project.

This article explores the unique properties of stainless steel flat washers, their wide-ranging applications, and the key considerations that users should keep in mind when selecting and using them. From corrosion resistance to load distribution, from automotive systems to household appliances, we’ll dive into everything you need to know about this critical hardware component.

What Are Stainless Steel Flat Washers?

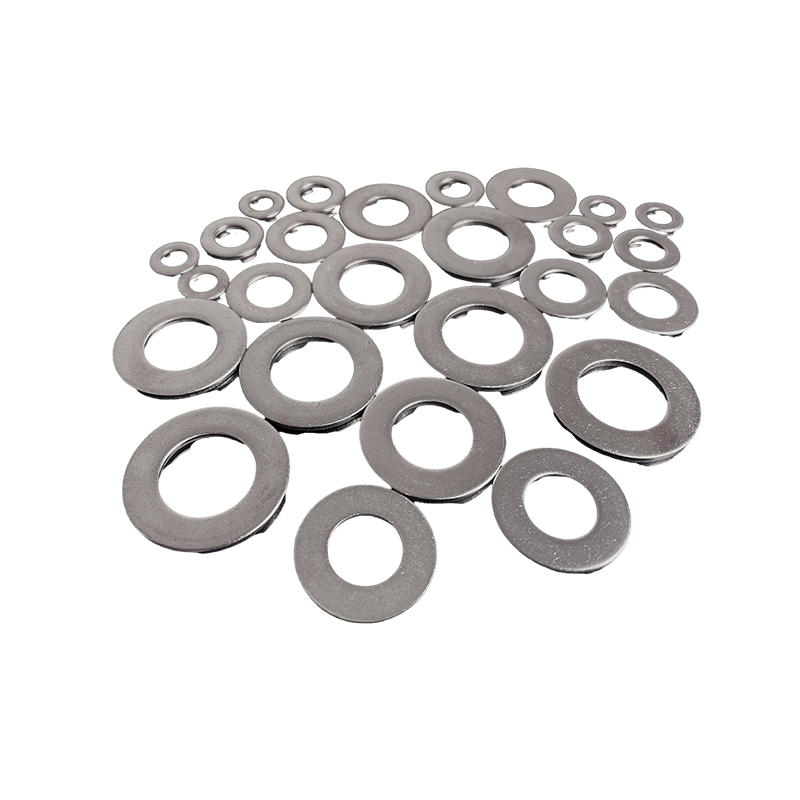

At first glance, a flat washer may seem like a simple metal ring with a hole in the center. However, its design and material composition are carefully engineered to fulfill specific mechanical roles. A flat washer is typically a thin, disk-shaped plate with a central hole designed to be placed beneath a nut or bolt head. Its primary purpose is to distribute the pressure exerted by the fastener over a larger area, reducing the risk of surface damage and loosening over time.

When made from stainless steel , the washer gains additional advantages such as:

Corrosion resistance

High strength and durability

Temperature resistance

Long service life

Aesthetic appeal

Stainless steel flat washers come in various sizes and thicknesses, conforming to international standards such as ISO, DIN, ANSI, and ASME, making them compatible with a broad range of fasteners and applications.

Key Features of Stainless Steel Flat Washers

1. Corrosion Resistance

One of the most notable features of stainless steel flat washers is their ability to resist rust and corrosion. This is primarily due to the chromium content in stainless steel, which forms a passive oxide layer on the surface, protecting the underlying metal from environmental exposure.

This makes them ideal for use in:

Marine environments

Chemical processing plants

Outdoor installations

High-humidity areas

2. Load Distribution

Flat washers serve an important mechanical function by distributing the clamping force of a bolt or screw over a wider area. Without a washer, concentrated pressure could deform the surface of the material being fastened—especially softer materials like wood, plastic, or aluminum.

Using a stainless steel flat washer helps prevent:

Surface indentation

Cracking or warping

Premature loosening of fasteners

3. Vibration Dampening

In dynamic environments where vibration is common—such as in vehicles, heavy machinery, or industrial equipment—fasteners can loosen over time. Stainless steel flat washers help absorb some of this movement, maintaining tension and preventing unwanted disassembly.

4. Electrical Insulation (Depending on Grade)

While not all stainless steel grades are insulative, certain types—particularly those with higher nickel and chromium content—can offer a degree of electrical insulation. This property can be beneficial in electronic assemblies or applications involving sensitive circuitry.

5. Temperature Resistance

Stainless steel retains its structural integrity under extreme temperatures, both high and low. Some grades can withstand:

High heat (up to 800°C or more)

Sub-zero cold without becoming brittle

This makes stainless steel flat washers suitable for use in:

Industrial ovens

Refrigeration units

Aerospace components

Cryogenic systems

Common Grades of Stainless Steel Used for Flat Washers

Not all stainless steel is created equal. Different alloys provide varying levels of performance depending on the environment and application. The most commonly used grades for flat washers include:

1. AISI 304 / 1.4301 (SS304)

Most widely used stainless steel grade

Good corrosion resistance in general environments

Excellent formability and weldability

Suitable for indoor and mild outdoor conditions

2. AISI 316 / 1.4401 (SS316)

Contains molybdenum, offering enhanced resistance to chlorides and marine environments

Ideal for coastal or chemical-exposed settings

Higher cost than SS304 but worth it for harsh conditions

3. AISI 430 / 1.4016

Lower corrosion resistance compared to 300-series

More affordable and magnetic

Often used in decorative applications or dry environments

Each grade has its own set of pros and cons, so choosing the right one depends heavily on the intended use and environmental conditions.

Applications Across Industries

The versatility of stainless steel flat washers means they are used in countless applications across nearly every industry. Here’s a look at some of the major sectors that rely on these essential components:

1. Construction and Architecture

In building construction, stainless steel flat washers are used to secure structural bolts, anchor points, and façade attachments. Their corrosion resistance ensures longevity, especially in exposed areas such as balconies, railings, and roofing systems.

2. Automotive Industry

From engine assembly to body panel fastening, flat washers help maintain proper tension and reduce wear caused by vibrations. In particular, stainless steel versions are favored in exhaust systems, undercarriage components, and other areas prone to moisture and heat.

3. Marine and Offshore Engineering

Due to their resistance to saltwater corrosion, stainless steel flat washers are extensively used in boatbuilding, offshore platforms, and port infrastructure. Choosing the correct grade (like SS316) is crucial in these highly corrosive environments.

4. Food Processing and Pharmaceutical Equipment

Stainless steel meets hygiene and sanitation requirements in food-grade and medical environments. Flat washers used here must also comply with strict regulations regarding material purity and ease of cleaning.

5. Electronics and Precision Instruments

Miniature stainless steel flat washers are used in circuit boards, sensors, and precision devices. Their non-magnetic properties (in certain grades) and dimensional stability make them ideal for delicate applications.

6. Household Appliances

Refrigerators, washing machines, ovens, and HVAC units often contain stainless steel flat washers to ensure long-lasting connections and minimize noise from vibration.

How to Choose the Right Stainless Steel Flat Washer

Selecting the appropriate flat washer involves more than just picking the right size. Several factors must be considered to ensure optimal performance and safety.

1. Determine the Fastener Size

Washers must match the diameter of the bolt or screw they accompany. Standard sizing follows metric or imperial measurements, so it's essential to verify compatibility before installation.

2. Material Grade Selection

As discussed earlier, the operating environment will dictate whether SS304, SS316, or another grade is most appropriate. Always consider exposure to moisture, chemicals, temperature extremes, and physical stress.

3. Thickness and Hardness

Thicker washers can handle heavier loads, while thinner ones are better suited for fine-tuning adjustments or limited spaces. Hardness levels also affect how well the washer can resist deformation under pressure.

4. Surface Finish

Stainless steel flat washers come in different finishes such as polished, brushed, or passivated. While aesthetics may be secondary in industrial settings, they can be important in architectural or consumer-facing applications.

5. Certifications and Standards

Ensure that the washers meet relevant quality standards such as:

ISO 898-2 (mechanical properties of nuts)

DIN 125 (dimensions for flat washers)

ASTM F844 (standard specification for flat washers)

These certifications guarantee that the product has been tested and conforms to established performance criteria.

Installation Best Practices

Even the highest-quality stainless steel flat washer won’t perform well if installed incorrectly. Here are some tips for effective usage:

1. Use One Per Fastener

For optimal load distribution and anti-loosening effect, place a washer under each nut or bolt head. Avoid stacking multiple washers unless specifically required by the design.

2. Avoid Over-Tightening

Excessive torque can compress the washer beyond its elastic limit, causing permanent deformation and loss of functionality. Use calibrated tools to apply the recommended tightening force.

3. Check for Proper Fit

Ensure the inner diameter of the washer matches the bolt size precisely. Too loose can lead to slippage; too tight can cause binding or damage to the fastener.

4. Pair with Compatible Materials

Avoid mixing dissimilar metals that could cause galvanic corrosion. For example, pairing stainless steel with aluminum in a wet environment may accelerate degradation unless properly insulated.

5. Regular Inspection and Maintenance

In critical applications, periodic inspection of washers is advisable to check for signs of wear, corrosion, or flattening. Replace any damaged washers promptly to avoid system failure.

Environmental and Economic Benefits

Beyond their technical advantages, stainless steel flat washers also contribute positively to sustainability and cost efficiency.

1. Long Lifespan Reduces Waste

Their durability means fewer replacements over time, resulting in less material waste and reduced maintenance costs.

2. Recyclable Material

Stainless steel is 100% recyclable, making it an eco-friendly choice for environmentally conscious manufacturers and consumers.

3. Energy Efficiency in Production

Modern production techniques have improved the energy efficiency of stainless steel manufacturing, further enhancing its green credentials.

4. Cost-Effective in the Long Run

Although stainless steel may cost more upfront than carbon steel or plated alternatives, its long service life and minimal maintenance requirements make it a more economical option over time.

Innovations and Future Trends

As industries evolve, so do the demands placed on fastening components. Recent advancements in materials science and manufacturing technology have led to several innovations in stainless steel flat washers:

1. Customized Shapes and Sizes

With CNC machining and laser cutting, manufacturers can now produce washers tailored to specific geometries and tolerances, expanding their usability in niche applications.

2. Coated Variants

Some stainless steel washers are now available with additional coatings (e.g., PTFE, zinc, or ceramic) to enhance performance in specialized environments.

3. Smart Fastening Systems

Emerging technologies integrate sensors into fastening systems, allowing real-time monitoring of tension and wear. While still in development, stainless steel washers are being adapted to work within these smart systems.

4. Additive Manufacturing (3D Printing)

Though not yet mainstream for mass-produced washers, 3D printing offers potential for creating complex washer designs on demand, particularly in aerospace and biomedical fields.

Why are Stainless Steel Flat Washers indispensable in mechanical equipment?

In mechanical equipment, although stainless steel flat washers are small in size, they play a vital role. They are widely used in various mechanical systems, building structures and pipeline connections, and are important components to ensure the safe operation of equipment and extend its service life.

Main functions of stainless steel flat washers

1. Disperse loads and prevent indentations

When bolts or nuts are tightened, a large concentrated pressure will be generated. If it acts directly on the surface of the connected parts, it is easy to cause local deformation, indentation or even damage. Stainless steel flat washers effectively disperse these pressures by expanding the contact area, thereby protecting the surface of the connected parts from damage.

For example, in precision instruments, electronic equipment or composite materials, the use of stainless steel flat washers can avoid functional failure caused by indentations.

2. Prevent loosening and enhance the tightening effect

In mechanical equipment where vibration, impact or thermal expansion differences frequently occur, threaded connections are prone to loosening. Although stainless steel flat washers do not have the active anti-loosening function like spring washers, they reduce the loss of preload caused by uneven surfaces by providing a uniform support surface, which indirectly prevents loosening.

In addition, it can also be used with locking nuts and spring washers to form a more stable anti-loosening combination.

3. Provide anti-corrosion protection

Stainless steel itself has good corrosion resistance, especially in humid, acidic, alkaline or salt spray environments, and can remain stable for a long time. Compared with ordinary carbon steel washers, stainless steel flat washers are not easy to rust, which can effectively avoid the problem of fastener failure caused by corrosion.

Especially in harsh environments such as ships, offshore platforms, and chemical equipment, stainless steel flat washers have become an indispensable connection element.

4. Compensate for surface unevenness

In actual applications, there are often manufacturing errors or installation deviations on the contact surfaces of connectors. Stainless steel flat washers can fill these tiny unevenness, make the bolts more evenly stressed, and improve the stability of the overall connection.

This compensation effect is particularly important in large-scale mechanical equipment and steel structure connections.

5. Increase sealing (auxiliary)

Although stainless steel flat washers are not specifically used for sealing, in some cases, they can assist seals (such as O-rings and gaskets) to play a better role and reduce the risk of leakage. For example, in flange connections, the presence of gaskets helps maintain the flatness and consistency of the sealing surface.

Application of stainless steel flat washers in different mechanical equipment

1. Industrial machinery (such as machine tools, compressors)

Industrial equipment is often in a state of high-speed operation and high-frequency vibration, and the stability of fasteners is extremely high. Stainless steel flat washers not only enhance the connection strength, but also greatly improve the reliability and service life of the equipment due to their wear resistance and fatigue resistance.

2. Automobile manufacturing and maintenance

Stainless steel flat washers are widely used in automobile chassis, engines, exhaust systems and other parts to cope with complex and changing working temperatures, humidity and chemical corrosion environments. Especially at the exhaust pipe connection, the high temperature resistance of stainless steel materials is particularly critical.

3. Aerospace equipment

In the field of aerospace, the selection of materials is extremely strict. Stainless steel flat washers are widely used in aircraft structures, engine components and satellite equipment due to their high strength, light weight (relatively speaking), corrosion resistance and ability to adapt to extreme temperatures.

4. Pipeline systems and valves

In industries such as oil, natural gas, and water treatment, pipeline connections need to withstand high pressure and corrosive media. Stainless steel flat washers can not only enhance the stability of the connection in such occasions, but also prevent leakage caused by corrosion.

5. Construction Engineering and Bridge Structures

In steel structure connections, stainless steel flat washers can prevent stress concentration caused by oxidation or uneven processing of steel surfaces, while improving the safety and aesthetics of the overall structure.

Precautions for selecting stainless steel flat washers

Material matching: Select the appropriate stainless steel grade according to the working environment, such as 316 for marine environments and 304 for general industries.

Dimensional accuracy: The inner diameter, outer diameter and thickness should be selected strictly according to the bolt specifications to ensure good fit.

Surface treatment: Polishing, passivation and other treatments are required in some occasions to enhance corrosion resistance or aesthetics.

Installation specifications: Correct installation position and order (such as washers first and nuts later) to avoid incorrect installation affecting performance.

Although stainless steel flat washers are small, they are indispensable basic components in mechanical equipment. They play an important role in bearing, anti-loosening, anti-corrosion, sealing and other aspects, and are one of the key factors to ensure safe and stable operation of equipment. With the development of industrial technology, the requirements for connectors are increasing day by day, and the application scope of stainless steel flat washers will continue to expand. In the future, with the continuous emergence of new materials and new processes, stainless steel flat washers will continue to play an important role in modern mechanical systems.

Common Misunderstandings of Using Stainless Steel Flat Washers in Auto Repair

In the process of automobile maintenance, Stainless Steel Flat Washers are a common and important fastener accessories. Their main function is to disperse the pressure applied by bolts or nuts, prevent the connection surface from being damaged, and play a role in preventing loosening and sealing to a certain extent. However, in actual operation, many maintenance personnel have some misunderstandings about the use of stainless steel flat washers, which may not only affect the quality of maintenance, but also cause safety hazards. The following are several common usage misunderstandings and their analysis:

Misunderstanding 1: Thinking that stainless steel is omnipotent and there is no need to consider the application scenario

Many maintenance personnel mistakenly believe that as long as it is a stainless steel flat washer, it can be used in all environments, especially in high temperature and corrosive environments, and it does not need to be replaced. In fact, different grades of stainless steel (such as 304, 316, etc.) have different corrosion resistance and temperature resistance. For example, 316 stainless steel has better resistance to chloride ion corrosion than 304, and is more suitable for use in marine or chemical environments. If 304 stainless steel washers are still used in a high-salinity environment (such as vehicles in coastal areas), rust may occur after long-term use, affecting the reliability of the connection.

Misconception 2: Blindly pursuing "bigger and thicker" is better

In order to enhance the connection strength, some maintenance personnel will choose stainless steel flat washers that are too large or too thick. In fact, the size of the washer should match the bolt or nut. If the inner diameter of the washer is too large, it will cause uneven force; if the outer diameter is too large, it may exceed the installation space limit and cause interference; and too thick washers may change the preload distribution of the connector, and even cause abnormal thread force, causing loosening or breakage risks.

Misconception 3: Ignoring the principle of matching washers

In some cases, maintenance personnel only pay attention to whether stainless steel washers are used, but ignore their matching with other fasteners (such as spring washers and locking nuts). For example, in areas with strong vibration, using only flat washers cannot effectively prevent loosening, and must be used in combination with spring washers or nylon locking nuts. Otherwise, even if stainless steel washers are used, parts may fall off or mechanical failures may occur due to connection failure.

Myth 4: Reusing deformed or worn washers

Since stainless steel is hard, some maintenance personnel mistakenly believe that washers are not easy to damage and can be used repeatedly. But in fact, the washers may have undergone plastic deformation or surface wear during the disassembly process. When used again, the pressure will not be evenly dispersed, and it may even scratch the connection surface or reduce the sealing performance. Especially in key parts such as the engine and exhaust system, it is recommended to replace new stainless steel flat washers after each disassembly.

Myth 5: Ignoring the problem of electrochemical corrosion

Although stainless steel is corrosion-resistant, it is prone to electrochemical corrosion (Galvanic Corrosion) when it comes into contact with other metals (such as carbon steel and aluminum), especially in the presence of moisture or electrolyte. For example, using a stainless steel washer between an aluminum alloy cylinder head and a stainless steel bolt may accelerate the corrosion of the aluminum if it is not insulated or coated with anti-corrosion paste. Therefore, special attention should be paid to the compatibility between materials in the connection of dissimilar metals, and insulating gaskets or anti-corrosion coatings should be used when necessary.

Correct use suggestions:

Choose the right grade of stainless steel washers according to the working environment;

Make sure the size of the washers matches the bolts/nuts to avoid being too large or too small;

Use spring washers or lock nuts in places where loosening is required;

Check and replace deformed, worn or corroded washers regularly;

Pay attention to the electrochemical corrosion problem between dissimilar metals and take protective measures.

Although stainless steel flat washers are small, they play an important role in car maintenance. Correctly understanding and using them can not only improve the quality of maintenance, but also extend the service life of the vehicle and ensure driving safety. Maintenance personnel should abandon empiricism and the thinking of "replacing small with large" and strictly follow technical specifications to truly play the role that stainless steel washers should play.

Stainless steel flat washers may appear small and unassuming, but their impact on mechanical systems is profound. From improving load distribution and preventing corrosion to enabling safe operation in extreme conditions, these components are vital in both everyday and high-stakes applications.

Whether you’re working on a DIY project, managing a factory floor, or designing next-generation equipment, understanding the value of stainless steel flat washers can significantly enhance the reliability and longevity of your work. As technology continues to advance, so too will the capabilities of these humble yet powerful parts, ensuring they remain a cornerstone of modern engineering and manufacturing.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)