Introduction to Stainless Steel Cap Nuts

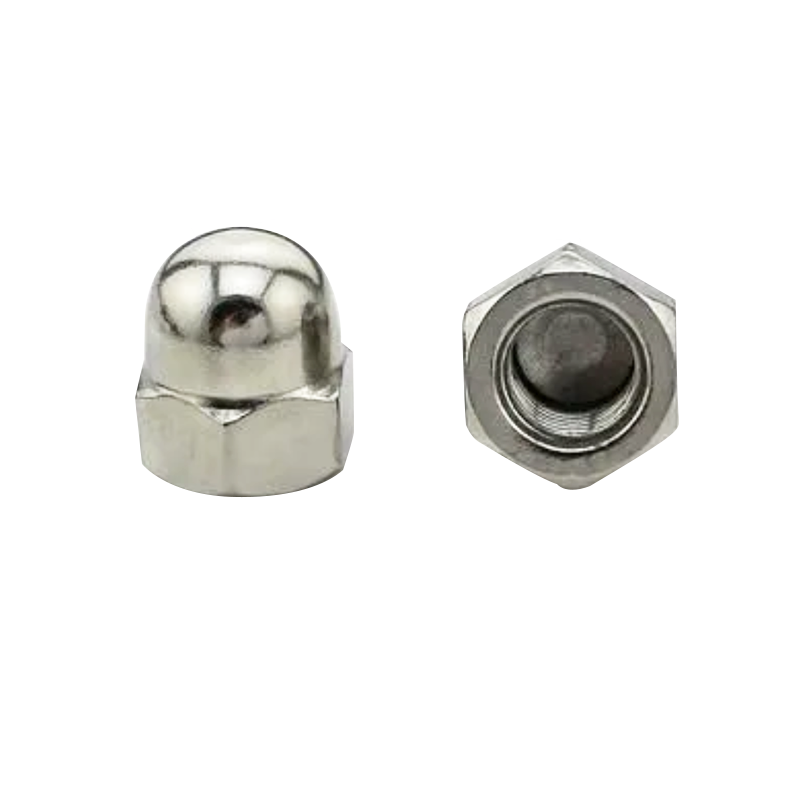

In the world of fasteners, stainless steel cap nuts stand out as a versatile and reliable choice for both industrial and consumer applications. These small but essential components serve a dual purpose—securing threaded rods or bolts while also providing an aesthetically pleasing finish. Unlike standard hex nuts, which are primarily functional, cap nuts offer a protective cover over the bolt end, reducing exposure to environmental elements and improving visual appeal.

Made from corrosion-resistant stainless steel, these nuts combine durability with elegance. Whether used in outdoor equipment, automotive assemblies, or household fixtures, their ability to withstand harsh conditions makes them a preferred option across multiple sectors. This article explores the unique features of stainless steel cap nuts, delves into their wide-ranging applications, and addresses key considerations that users often evaluate when selecting fasteners for specific projects.

What Makes Stainless Steel Cap Nuts Unique?

1. Corrosion Resistance and Longevity

One of the most defining characteristics of stainless steel cap nuts is their inherent resistance to corrosion. Stainless steel, particularly grades such as 304 and 316, contains chromium, which forms a passive oxide layer on the surface. This layer acts as a shield against moisture, chemicals, and other corrosive agents, significantly extending the lifespan of the nut.

This feature is especially valuable in environments where exposure to saltwater, humidity, or industrial pollutants is common. For instance, marine hardware, coastal infrastructure, and chemical processing equipment benefit immensely from the use of stainless steel cap nuts.

2. Aesthetic Appeal and Finishing Touch

Beyond functionality, cap nuts are known for their clean, finished appearance. The domed top design conceals the bolt end, offering a smooth and polished look. This makes them ideal for visible applications where aesthetics matter—such as furniture, decorative railings, and architectural structures.

The shiny surface of polished stainless steel enhances the visual appeal without requiring additional coatings or paint, making it a low-maintenance solution for designers and builders alike.

3. Mechanical Strength and Load-Bearing Capacity

Despite their compact size, stainless steel cap nuts are engineered to provide strong mechanical performance. They maintain high tensile strength and can withstand significant torque during installation. When paired with compatible bolts, they ensure secure fastening even under dynamic loads.

Moreover, the threading precision ensures minimal slippage and a snug fit, contributing to overall structural integrity. This reliability is crucial in applications ranging from machinery assembly to load-bearing frameworks.

Common Applications of Stainless Steel Cap Nuts

1. Automotive Industry

In the automotive sector, stainless steel cap nuts are frequently used in under-the-hood components, exhaust systems, and exterior trim. Their resistance to heat and corrosion allows them to perform well in high-temperature environments, where ordinary fasteners might degrade over time.

Additionally, their sleek appearance complements the vehicle’s aesthetic, especially in custom builds and luxury models where exposed fasteners need to blend seamlessly with the design.

2. Marine and Outdoor Equipment

Boats, docks, trailers, and outdoor recreational gear often rely on stainless steel cap nuts due to their excellent resistance to saltwater corrosion. These nuts protect critical joints and connections from rust and degradation, ensuring safety and longevity in harsh marine environments.

For example, deck fittings, anchor points, and railing installations commonly use cap nuts to secure hardware while maintaining a clean, uncluttered appearance.

3. Construction and Architecture

Architectural applications, including handrails, balustrades, and structural supports, benefit greatly from the combination of strength and aesthetics provided by cap nuts. Stainless steel's durability ensures that these fasteners remain intact even in high-traffic areas or regions with fluctuating weather conditions.

Designers appreciate the ability to integrate fasteners into the overall structure without compromising on visual harmony, making cap nuts a popular choice in modern construction projects.

4. Furniture and Interior Fixtures

Furniture makers and interior designers favor stainless steel cap nuts for assembling tables, chairs, shelves, and cabinetry. The clean finish complements contemporary styles, while the material’s strength ensures stability and safety.

These nuts are especially useful in modular furniture that requires frequent assembly and disassembly, as they provide a secure yet visually discreet connection point.

5. Industrial Machinery and Equipment

Industrial settings demand fasteners that can endure constant vibration, thermal expansion, and mechanical stress. Stainless steel cap nuts meet these requirements by offering consistent performance under challenging conditions.

They are commonly found in conveyor systems, pumps, valves, and heavy-duty manufacturing equipment, where secure fastening is critical to operational efficiency and worker safety.

Choosing the Right Stainless Steel Cap Nut

Selecting the appropriate cap nut involves considering several factors to ensure compatibility, performance, and longevity. Here are some key aspects to keep in mind:

1. Material Grade Selection

Stainless steel comes in various grades, each with different properties suited to specific environments:

Grade 304 (A2) : General-purpose stainless steel with good corrosion resistance. Suitable for indoor and mildly corrosive environments.

Grade 316 (A4) : Contains molybdenum, enhancing resistance to chlorides and seawater. Ideal for marine and chemical applications.

Other Grades : Less common variants like 410 or 430 may be used in non-corrosive settings where cost is a primary concern.

Choosing the right grade depends on the expected exposure to moisture, chemicals, and temperature extremes.

2. Thread Size and Pitch

Cap nuts must match the thread size and pitch of the corresponding bolt or rod. Standard metric and imperial sizes are available, with variations in coarse and fine threading. Ensuring proper alignment prevents cross-threading and maintains joint integrity.

Common sizes include M6, M8, M10 in metric units, and 1/4", 5/16", 3/8" in imperial measurements.

3. Finish Options

While polished stainless steel offers a bright, reflective surface, other finishes may be chosen based on application needs:

Satin or Brushed Finish : Reduces glare and hides fingerprints, suitable for architectural and decorative uses.

Black Oxide or Coated Variants : Provide additional protection in certain environments and offer color customization options.

Each finish has its own maintenance and wear characteristics, so selection should align with usage conditions.

4. Installation Tools and Techniques

Proper installation is crucial to achieving optimal performance from cap nuts. Depending on the size and accessibility, tools such as open-end wrenches, socket sets, or impact drivers may be used.

It’s important to avoid over-tightening, which can strip threads or deform the nut. Torque specifications should be followed to ensure secure fastening without damaging the components.

Advantages Over Other Types of Nuts

When compared to alternative fasteners like hex nuts, wing nuts, or acorn nuts, stainless steel cap nuts offer distinct advantages:

1. Superior Corrosion Protection

Unlike zinc-plated or galvanized nuts, stainless steel cap nuts do not require additional coatings to resist corrosion. Their inherent material properties make them more durable in aggressive environments.

2. Enhanced Visual Presentation

Cap nuts provide a cleaner, more finished look than standard nuts, which often leave exposed bolt ends. This makes them preferable in visible or decorative applications.

3. Ease of Maintenance

Due to their corrosion resistance and lack of coating that could chip or peel, stainless steel cap nuts require minimal upkeep. Occasional cleaning with mild detergent is usually sufficient to maintain their appearance and function.

4. Versatility Across Industries

Their adaptability allows them to be used in everything from aerospace components to garden furniture, bridging the gap between utility and design.

Potential Limitations and Considerations

While stainless steel cap nuts offer many benefits, there are some limitations and considerations to be aware of:

1. Cost Compared to Other Materials

Stainless steel is generally more expensive than carbon steel or aluminum. In large-scale projects or applications where corrosion resistance isn't a priority, this cost factor may influence material selection.

2. Limited Reusability

Once installed, cap nuts can sometimes become difficult to remove without damaging the surrounding area or the nut itself. This is especially true in tight spaces or after prolonged exposure to the elements.

3. Not Always Suitable for High-Torque Applications

Although cap nuts are strong, they may not be the best choice for extremely high-torque situations where larger or specialized locking nuts are required. It's important to assess the mechanical demands before selecting this type of fastener.

Environmental and Sustainability Aspects

As industries move toward greener practices, the sustainability of materials becomes increasingly important. Stainless steel cap nuts contribute positively in several ways:

1. Recyclability

Stainless steel is one of the most recycled materials globally, with high recovery rates in both industrial and consumer sectors. At the end of their service life, cap nuts can be melted down and reused without loss of quality.

2. Longevity Reduces Waste

Their long lifespan means fewer replacements and less waste generation over time. This makes them a sustainable option for long-term installations.

3. Low Emissions During Production

Modern stainless steel production methods have significantly reduced energy consumption and emissions, making it a more environmentally friendly material choice compared to older manufacturing processes.

Conclusion: Why Stainless Steel Cap Nuts Are a Preferred Choice

Stainless steel cap nuts represent a perfect balance between form and function. Their robust construction, combined with aesthetic appeal and environmental resilience, makes them indispensable across a wide range of industries. Whether securing a boat trailer, assembling a modern office chair, or reinforcing a commercial building, these fasteners deliver reliability and style.

By understanding the key features, applications, and selection criteria outlined above, users can make informed decisions that enhance both the performance and appearance of their projects. As technology and design continue to evolve, stainless steel cap nuts will likely remain a staple in the fastener industry, meeting the ever-growing demand for durable, attractive, and sustainable solutions.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)