Introduction to Stainless Steel Square Nuts

Stainless steel square nuts are essential fastening components widely used in industrial, construction, and mechanical applications. Characterized by their four-sided design, these nuts provide greater surface contact with the material being fastened, resulting in higher stability and resistance to loosening compared to hex nuts in certain applications. Known for their corrosion resistance, durability, and versatility, stainless steel square nuts are ideal for environments where exposure to moisture, chemicals, or extreme conditions is expected. This article provides a comprehensive guide to stainless steel square nuts, including types, dimensions, applications, installation techniques, and maintenance practices.

Material Properties and Advantages

1. Corrosion Resistance

Stainless steel square nuts are highly resistant to corrosion, making them suitable for outdoor, marine, and chemical environments. The chromium content in stainless steel forms a protective oxide layer on the surface, preventing rust and prolonging the lifespan of the fastener. This property makes them ideal for use in harsh conditions, such as construction sites, chemical plants, and food processing equipment.

2. Mechanical Strength

Stainless steel square nuts exhibit excellent mechanical strength, providing reliable fastening and load-bearing capacity. Depending on the grade, these nuts can withstand high tensile and shear forces, ensuring structural stability. They are available in grades such as 304 and 316 stainless steel, with 316 offering superior resistance to aggressive chemical environments.

3. Temperature Resistance

These nuts can endure a wide range of temperatures without losing strength or becoming brittle. Stainless steel performs well in both high-temperature industrial applications and low-temperature environments, making square nuts suitable for use in machinery, engines, and outdoor installations.

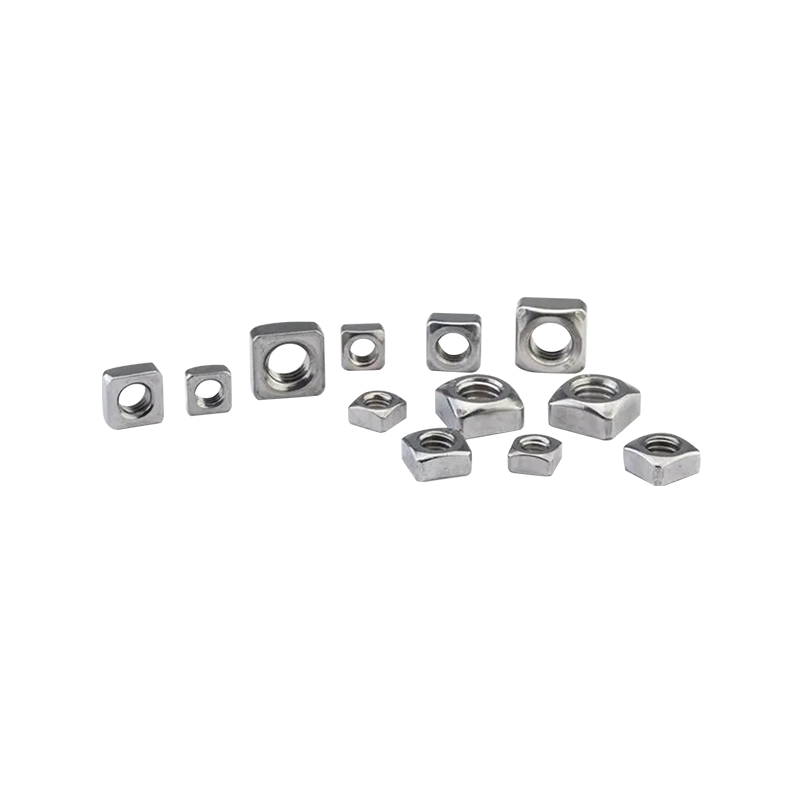

Types and Sizes of Stainless Steel Square Nuts

1. Standard Square Nuts

Standard stainless steel square nuts conform to international standards such as DIN 557 or ANSI B18.2.2. They are available in a variety of thread sizes and thicknesses, making them suitable for general mechanical and structural applications. These nuts are used where high torque and secure fastening are required.

2. Heavy-Duty Square Nuts

Heavy-duty square nuts are thicker and more robust than standard versions, providing additional strength and resistance to deformation. They are commonly used in industrial machinery, steel structures, and construction applications where load-bearing capacity is critical. These nuts often pair with square bolts or threaded rods for maximum stability.

3. Weldable and Jam Nuts

Weldable stainless steel square nuts have flat surfaces that allow them to be securely welded onto metal surfaces, providing permanent fastening points. Jam nuts are thinner square nuts designed to lock standard nuts in place, preventing loosening due to vibration. Both types are widely used in automotive, construction, and machinery applications.

Applications of Stainless Steel Square Nuts

1. Construction and Structural Engineering

Stainless steel square nuts are extensively used in construction projects, including steel frameworks, bridges, and heavy machinery assembly. Their large contact area provides enhanced resistance to loosening, making them suitable for structural applications where stability is crucial. These nuts are often used with square washers or embedded in channels for secure fastening.

2. Mechanical and Industrial Equipment

Industrial machinery, manufacturing equipment, and mechanical assemblies frequently utilize square nuts for reliable fastening. They provide stable torque distribution and are compatible with machinery components that experience vibration or dynamic loads. Stainless steel ensures long-term durability even under continuous operational stress.

3. Outdoor and Marine Applications

Outdoor structures such as railings, signage, and marine equipment benefit from stainless steel square nuts due to their corrosion resistance. They withstand exposure to rain, humidity, and saltwater, ensuring that fasteners remain secure and functional over time. These nuts are often paired with stainless steel bolts and washers for full corrosion protection.

4. Automotive and Transportation

In automotive applications, square nuts are used in chassis assemblies, vehicle frames, and mechanical components where high torque and vibration resistance are required. Their ability to maintain structural integrity under dynamic loads enhances safety and reliability in vehicles, trains, and heavy equipment.

Installation Guidelines

1. Thread Compatibility

Ensure that the square nut matches the bolt or threaded rod in terms of thread size, pitch, and grade. Using incompatible threads can lead to stripping, reduced load capacity, and unsafe connections. Standard metric or imperial threads should be verified before installation.

2. Proper Torque Application

Applying correct torque is essential to prevent over-tightening, which can deform the nut or bolt, and under-tightening, which can cause loosening. Torque specifications provided by the manufacturer should be followed, and torque wrenches are recommended for precise installation.

3. Use of Washers and Locking Devices

Washers, lock washers, or jam nuts are often used with stainless steel square nuts to enhance stability and prevent loosening due to vibration. Flat washers distribute load evenly, while lock washers provide additional resistance to rotational forces.

Maintenance and Longevity

1. Regular Inspections

Periodic inspection of square nuts is recommended to ensure that fasteners remain tight and free from corrosion. Visual checks can identify signs of wear, rust, or loosening, allowing for timely maintenance and replacement if necessary.

2. Cleaning and Corrosion Prevention

Stainless steel square nuts can accumulate dirt, debris, or chemical residues. Cleaning with mild detergents and water helps maintain appearance and function. For marine or high-corrosion environments, applying anti-corrosion coatings or lubricants can further extend the lifespan of fasteners.

3. Replacement and Standards Compliance

Replace damaged or worn square nuts promptly to ensure structural integrity and safety. Always use nuts that comply with relevant industry standards such as DIN, ISO, or ASTM. Adhering to quality standards ensures compatibility, strength, and longevity in industrial and construction applications.

Conclusion

Stainless steel square nuts are vital components in a wide range of industrial, construction, and mechanical applications. Their corrosion resistance, mechanical strength, and durability make them suitable for demanding environments, including outdoor, marine, and high-vibration settings. Understanding the types, applications, installation methods, and maintenance practices ensures optimal performance, safety, and longevity of these fasteners. Investing in high-quality stainless steel square nuts guarantees reliable and secure connections across various industries.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)