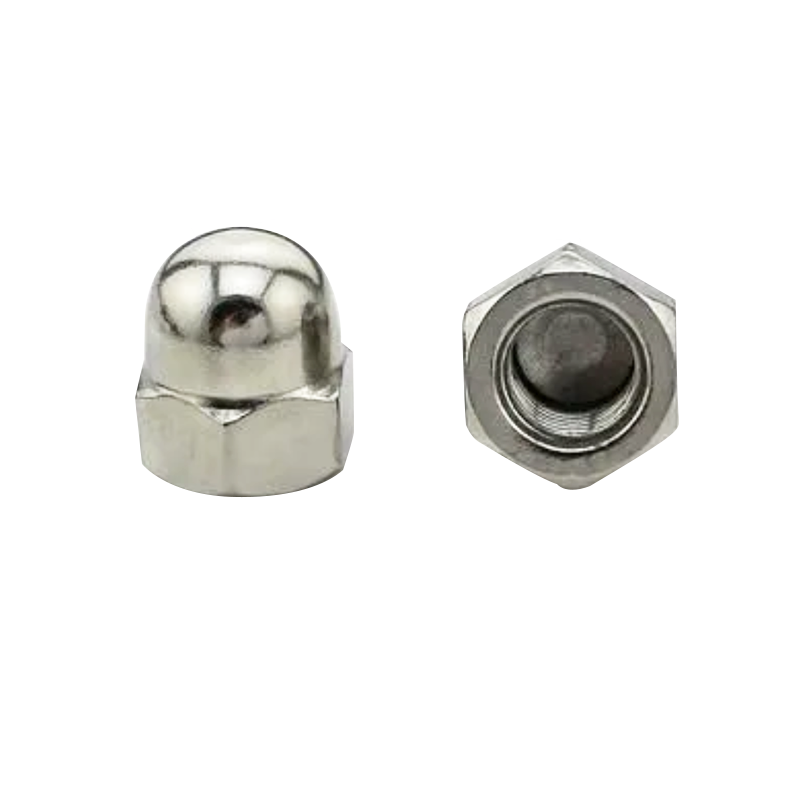

Fasteners may seem like small, simple components, but they play a critical role in construction, machinery, and everyday applications. Among the many types of nuts available, stainless steel cap nuts—also known as acorn nuts or domed nuts—stand out because of their unique design. Characterized by a rounded dome on one side, these nuts not only secure bolts but also provide aesthetic and functional advantages. To understand their value, it is important to look at what stainless steel cap nuts are used for, why they are chosen over standard nuts, and in which industries they are most common.

1. Basic Function of Cap Nuts

At their core, cap nuts serve the same purpose as any nut: they fasten onto the threaded end of a bolt or screw to hold materials together. However, unlike regular hex nuts, cap nuts have a closed dome that covers the exposed threads. This seemingly small difference provides several key benefits:

Protection of Threads: The dome shields the bolt threads from damage, corrosion, or dirt.

Improved Safety: By covering sharp or protruding ends, cap nuts prevent cuts, snags, and accidental injuries.

Enhanced Appearance: The smooth, polished look gives projects a finished and professional appearance.

Because of these advantages, cap nuts are often selected when both function and appearance matter.

2. Why Stainless Steel?

Cap nuts can be made from various materials, but stainless steel is especially popular because of its:

Corrosion Resistance: Ideal for outdoor or marine environments, stainless steel withstands moisture, rain, and salt without rusting easily.

Strength and Durability: Stainless steel offers long-lasting performance, even under heavy loads.

Low Maintenance: Unlike plain steel, stainless steel cap nuts do not require special coatings or frequent replacements.

Attractive Finish: Their natural shine suits decorative and visible applications.

This combination of strength, beauty, and resistance makes stainless steel cap nuts versatile across many industries.

3. Common Uses in Different Industries

Stainless steel cap nuts are applied in a wide range of settings:

a. Automotive Industry

In cars, motorcycles, and bicycles, cap nuts secure wheels, engines, and body parts. The dome not only protects threads from dirt and road grime but also adds a clean, polished look to exposed fasteners. Custom car builders and motorcycle enthusiasts often prefer stainless steel cap nuts for both durability and style.

b. Furniture and Home Fixtures

Furniture makers use cap nuts to cover bolt ends in chairs, tables, and beds. This prevents scratches on floors or clothing and reduces the risk of injury from sharp threads. In kitchens and bathrooms, stainless steel’s resistance to moisture makes cap nuts a smart choice for fixtures.

c. Construction and Architecture

In building projects, exposed fasteners can look unattractive. Stainless steel cap nuts provide a neat finish on railings, gates, handrails, and architectural structures. They are particularly common in stainless steel balustrades and outdoor installations where weather resistance is essential.

d. Marine Applications

Boats, docks, and seaside equipment require hardware that can resist saltwater corrosion. Stainless steel cap nuts are often used to fasten fittings and fixtures in these environments, ensuring long-term reliability.

e. Machinery and Equipment

Industrial machines often use cap nuts on moving parts to protect threads and operators alike. The dome prevents loose clothing or materials from catching on exposed bolts, improving workplace safety.

4. Decorative and Aesthetic Uses

Beyond practicality, stainless steel cap nuts are valued for their visual appeal. Their polished dome makes them ideal for decorative projects such as:

Display stands

Lighting fixtures

Garden furniture

Public installations

In these cases, the nut serves both as a fastener and as part of the design.

5. Safety and Protective Benefits

One of the main reasons for using cap nuts is safety. Exposed bolt threads can easily cause cuts, punctures, or snagging. In environments where people frequently come into contact with machinery or furniture—such as playgrounds, gyms, and public spaces—cap nuts significantly reduce injury risks. By choosing stainless steel, users also ensure that the protective dome remains intact even after years of exposure.

6. Specialized Applications

Stainless steel cap nuts are also found in more specialized areas:

Electronics and Appliances: To protect sensitive parts from dust and accidental contact.

Medical Equipment: Where both hygiene and smooth finishes are important.

Sports Equipment: On bicycles, gym machines, or outdoor gear that requires both strength and user safety.

So, what are stainless steel cap nuts used for? In short, they are used wherever strength, safety, protection, and appearance are important. From securing bolts in cars and furniture to protecting machinery and enhancing architectural projects, stainless steel cap nuts provide practical benefits alongside visual appeal. Their resistance to corrosion ensures reliability in outdoor, marine, and industrial environments, while their smooth dome adds an extra layer of safety for people and equipment.

Though they may seem like small hardware pieces, stainless steel cap nuts play an essential role in many industries. By combining durability with elegance, they prove that even the smallest fasteners can make a big difference in both performance and design.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)