Stainless steel self-locking nuts are a type of fastener used to prevent loosening caused by vibration, torque, or other mechanical forces. They are commonly found in machinery, automotive, aerospace, construction, and even household appliances where reliability and durability are critical. These nuts combine the strength and corrosion resistance of stainless steel with a locking mechanism that ensures a secure fit over time.

Let’s explore what they are, how they work, and why they are so widely used.

1. Understanding the Basics

A nut is a standard hardware component that threads onto a bolt or screw to fasten two or more parts together. However, in dynamic environments—such as moving machines or vehicles—standard nuts can gradually loosen due to vibration or movement. That’s where self-locking nuts come into play.

Self-locking nuts are designed with features that resist loosening. When made of stainless steel, they also offer added benefits such as rust resistance, high strength, and long-lasting performance, even in harsh environments.

2. How Do Self-locking Nuts Work?

Unlike regular nuts, self-locking nuts include a locking mechanism. There are several designs, but the most common types include:

-

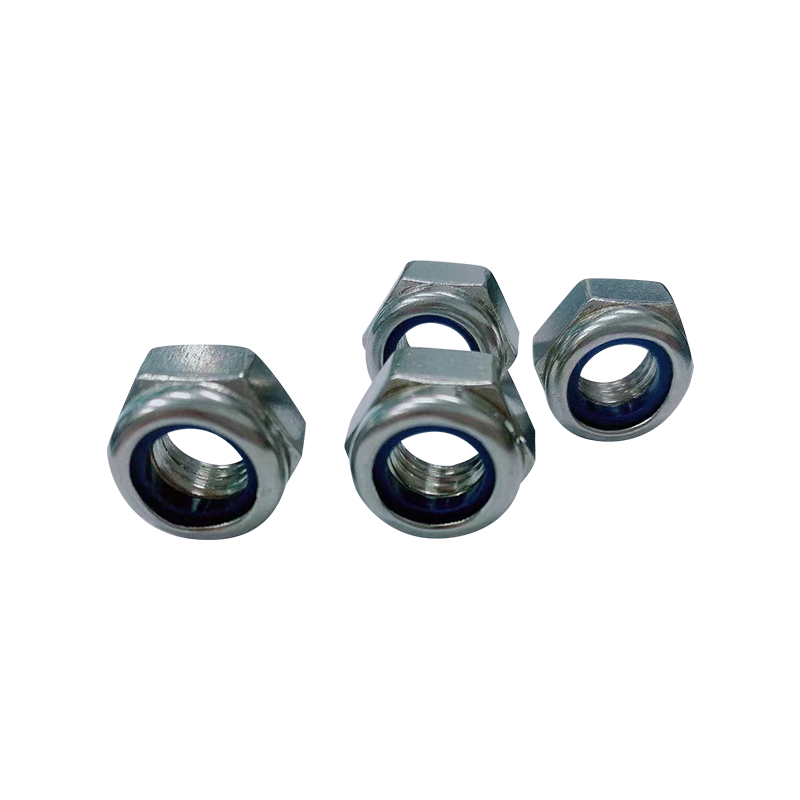

Nylon Insert Lock Nuts (Nylock nuts): These have a ring of nylon inserted at the top. When the nut is screwed onto a bolt, the threads cut into the nylon, creating resistance and holding the nut in place.

-

All-metal Lock Nuts: These rely on a deformed thread, slightly oval shape, or slotted design to create friction. They are better for high-temperature environments where nylon could melt.

-

Prevailing Torque Lock Nuts: These nuts create constant friction against the bolt threads to prevent movement.

In all these designs, the locking mechanism makes it difficult for the nut to come loose unintentionally, especially when exposed to vibration or thermal expansion.

3. Why Stainless Steel?

Stainless steel is a popular material choice for self-locking nuts due to several properties:

-

Corrosion Resistance: Stainless steel resists rust, making it ideal for outdoor, marine, or humid conditions.

-

Strength: It offers strong mechanical properties, capable of withstanding high levels of torque and load.

-

Temperature Tolerance: Stainless steel maintains its integrity in both high and low temperature environments.

-

Longevity: With proper use, stainless steel fasteners can last for years without degrading.

Common grades include 304 stainless steel (general use) and 316 stainless steel (higher corrosion resistance, suitable for marine environments).

4. Where Are Stainless Steel Self-locking Nuts Used?

Because of their durability and anti-loosening function, these nuts are used in a wide range of applications:

-

Automotive industry: To secure parts that are exposed to constant vibration, such as engines and suspension systems.

-

Aerospace industry: Where reliability is critical and bolts must stay tight under stress and changing conditions.

-

Machinery and Equipment: To ensure mechanical parts stay securely connected during operation.

-

Construction: In structural frameworks, bridges, and railings that need to resist wind or vibration.

-

DIY and Home Projects: For furniture, garden tools, or home repairs requiring dependable fasteners.

5. Advantages of Stainless Steel Self-locking Nuts

-

Prevents Loosening: Their main feature is the ability to resist vibration and stay tight over time.

-

Reusable (in many cases): Some types can be reused several times, although reusability depends on the locking style.

-

No Need for Additional Locking Tools: Unlike using a regular nut with washers or adhesives, self-locking nuts are one-piece solutions.

-

Weather-Resistant: Thanks to the stainless steel material, they can withstand rain, humidity, and even saltwater (especially 316 grade).

-

Clean Appearance: Stainless steel offers a sleek, clean look, especially important in visible or design-sensitive installations.

6. Limitations to Consider

While stainless steel self-locking nuts are incredibly useful, they also have some limitations:

-

Cost: Stainless steel is more expensive than carbon steel or zinc-plated nuts.

-

Galling: When tightening stainless steel against stainless steel, the materials can stick together, a phenomenon known as “thread galling.” Using anti-seize compounds or dissimilar metals can help prevent this.

-

Not Always Reusable: Nylon lock nuts can lose their grip after several uses as the nylon wears down.

-

Requires More Torque: Some locking nuts need more torque to install or remove due to the added resistance of the locking mechanism.

7. How to Identify a Stainless Steel Self-locking Nut

You can usually identify these nuts by looking for:

-

A nylon insert (for nylon types)

-

A slightly deformed or notched metal shape (for all-metal types)

-

A marking like “A2-70” or “A4-80”, indicating stainless steel grade

-

A shiny or matte metallic finish typical of stainless steel

Always check the product specifications or ask your supplier if you are unsure.

Stainless steel self-locking nuts are an essential component in modern fastening systems. By combining the strength and corrosion resistance of stainless steel with a built-in locking mechanism, they offer a reliable solution for keeping components secure in a variety of demanding environments.

Whether you’re building a car engine, assembling industrial machinery, or simply working on a home improvement project, these nuts provide peace of mind by preventing unexpected loosening—and ensuring that everything stays right where it belongs.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)