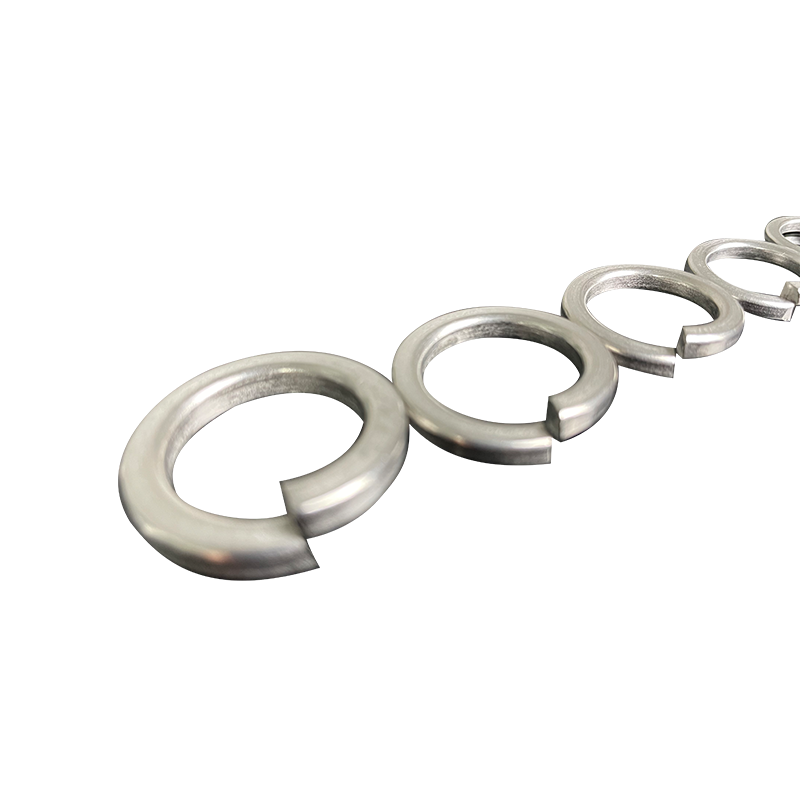

Stainless steel spring washers are essential components widely used in mechanical assemblies, automotive applications, construction, and various industrial equipment. They are designed to provide tension, absorb shock, and prevent loosening of fasteners in bolted connections. One common question that arises among engineers, technicians, and buyers is: Are stainless steel spring washers rust-proof? The answer requires a closer look at the material properties, environmental conditions, and maintenance practices.

Understanding Stainless Steel

Stainless steel is an alloy primarily composed of iron, chromium, and sometimes nickel or molybdenum. The addition of chromium—usually at least 10.5%—creates a thin, self-repairing oxide layer on the surface. This protective layer makes stainless steel resistant to corrosion and rust, which is why it is widely used in harsh environments.

However, it is important to note that “rust-proof” does not mean completely immune to corrosion. While stainless steel performs much better than ordinary steel or carbon steel, certain conditions can still lead to rust or surface degradation.

Why Stainless Steel Spring Washers Resist Rust

-

Chromium Oxide Layer

The chromium in stainless steel forms a passive oxide layer that protects the metal from moisture and oxygen. This layer prevents rust from forming under normal conditions. -

Nickel and Molybdenum Enhancements

Higher grades of stainless steel, such as 316, include nickel and molybdenum. These elements improve corrosion resistance, especially in salty or acidic environments, making the washers more durable in marine or chemical applications. -

Durability Under Stress

Spring washers are under constant tension. Stainless steel maintains its corrosion resistance even under mechanical stress, which helps prevent weakening or failure due to rust over time.

Limitations and Considerations

While stainless steel spring washers are highly corrosion-resistant, they are not completely rust-proof in all situations:

-

Chloride Exposure

Environments with high chloride content, such as seawater or road salt, can eventually lead to localized corrosion, often called pitting. Even high-grade stainless steel washers may show rust over long-term exposure. -

Poor Maintenance

Accumulated dirt, grease, or chemicals on the washer surface can compromise the protective oxide layer. Regular cleaning helps maintain corrosion resistance. -

Mechanical Damage

Scratches or deformation can damage the passive layer, exposing the metal underneath. If left untreated, this can lead to rust spots forming. -

Lower Stainless Steel Grades

Some stainless steel washers are made from lower grades such as 201 or 430, which offer less corrosion resistance compared to 304 or 316. Choosing the appropriate grade is crucial depending on the application.

Applications Where Rust Resistance Is Crucial

Stainless steel spring washers are often chosen for applications where corrosion resistance is critical:

- Marine Industry – Used in boats, docks, and offshore equipment due to exposure to saltwater.

- Automotive and Transport – Protect fasteners from road salt and moisture.

- Chemical Plants – Resist corrosion from acids, alkalis, and other chemicals.

- Outdoor Construction – Withstand weather exposure in bridges, railings, and outdoor machinery.

- Food and Beverage Industry – Maintain hygiene and prevent rust in equipment that contacts food.

In these environments, selecting the proper stainless steel grade (like 316 or 304) ensures maximum resistance to corrosion.

Best Practices for Maintaining Rust Resistance

Even stainless steel spring washers can benefit from proper maintenance:

- Clean Regularly – Remove dirt, salts, and chemicals to prevent surface damage.

- Inspect Frequently – Look for scratches, pitting, or discoloration, especially in harsh environments.

- Lubricate When Necessary – A thin protective coating of compatible lubricant can further prevent corrosion in extreme conditions.

- Choose the Right Grade – For marine or chemical applications, prefer 316 stainless steel over 304 or lower grades.

Conclusion

So, are stainless steel spring washers rust-proof? The answer is mostly yes, but with limitations. Stainless steel provides excellent resistance to rust due to its chromium-rich passive layer, which protects the washer from moisture and oxygen. High-grade stainless steel, like 316, offers superior performance in challenging environments such as saltwater, chemical exposure, and outdoor applications.

However, no material is entirely immune to corrosion. Environmental factors like high chloride exposure, mechanical damage, low-quality material, and lack of maintenance can eventually lead to rust formation. By selecting the appropriate stainless steel grade and following proper care practices, stainless steel spring washers can remain functional and corrosion-free for years, ensuring the stability and safety of mechanical assemblies.

In short, stainless steel spring washers are highly rust-resistant, making them a reliable choice for most industrial, automotive, and construction applications—but proper selection and care are key to maximizing their lifespan and performance.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)