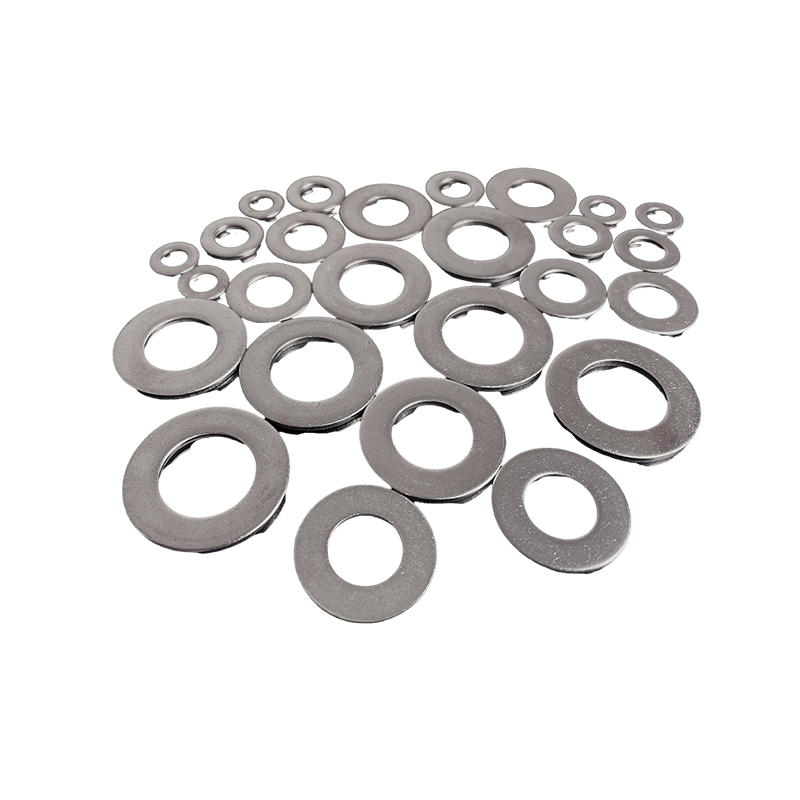

Overview: Why washer prices are more volatile

Stainless-steel washers are a low-margin, high-volume commodity whose price is determined not just by sheet or coil prices but by an interplay of feedstock costs, regional mill margins, freight and lead-time risk, and demand from construction, automotive and industrial OEMs. Recent years have shown that even modest moves in nickel, ferrochrome or scrap can transmit rapidly into washer quotes because thin-gauge processing and precision stamping add discrete unit costs that suppliers pass on quickly. This article breaks the main drivers into practical categories and ends with sourcing and inventory tactics for purchasers and suppliers. :contentReference[oaicite:0]{index=0}

Raw-material fundamentals: nickel, chromium and scrap

The most direct input to austenitic stainless (e.g., 304/316) is nickel and chromium content. Nickel price swings influence 300-series mills' raw-cost; ferrochrome affects 200/400-series grades and alloy premiums. When nickel or ferrochrome spikes, mills raise coil prices and service centers widen spreads. Conversely, weak stainless demand in a regional market (for example a slowdown in construction) can lead to exporters discounting inventory — causing short-term price drops followed by tightness when inventories deplete. :contentReference[oaicite:1]{index=1}

What purchasers should watch

Track LME nickel and ferrochrome indices, stainless scrap prices, and regional mill premiums. For contract negotiations, index-link clauses tied to nickel or scrap are common; buyers without index protection risk abrupt increases. :contentReference[oaicite:2]{index=2}

Logistics, freight and lead-time risk

Freight volatility and port congestion amplify price moves for commoditized parts like washers. Higher container rates or reduced sailings increase landed cost per kilogram, while longer lead times raise working-capital and safety-stock expenses. The impact is greatest for smaller buyers who cannot aggregate shipments: the per-unit freight share is higher and sudden rate spikes are harder to absorb. Recent UNCTAD and market analyses show that container costs and geopolitical routing issues have kept freight costs structurally above pre-crisis levels, which continues to transmit into import-dependent fastener prices. :contentReference[oaicite:3]{index=3}

Operational levers to reduce logistics exposure

- Consolidate purchase orders to full-container loads (FCL) when possible to lower per-unit freight.

- Use dual-sourcing between domestic and nearby regional mills to hedge lead-time risk.

- Negotiate freight-allocation clauses in long-term contracts or buy forward freight capacity during low-rate months.

Trade policy, tariffs and regionalization

Trade measures and shifting sourcing strategies have become pronounced price drivers. Tariffs or antidumping duties push buyers toward local mills or alternate origins, where supply tightness may support higher prices even if global raw-material costs fall. In some markets, post-tariff reshoring has allowed domestic mills to secure higher blended margins, which feeds through into distributor and component prices. Buyers exposed to duty risk should explicitly model landed cost including potential tariff scenarios. :contentReference[oaicite:4]{index=4}

Demand cycles and inventory dynamics for washers

Washers follow larger cyclical end-markets: construction, automotive, heavy equipment, electronics, and renewables. A surge in infrastructure spending or EV production raises demand for corrosion-resistant hardware; conversely, a slowdown in construction reduces stainless consumption. Because washers are produced in high volumes and small pack sizes, distributors often carry lower days-of-inventory relative to coils. That makes prices sensitive to sudden order uplifts or distributor stock-outs — situations where lead-time premiums appear quickly. Industry forecasts project steady growth in fasteners overall, but regional timing varies and creates transient tightness. :contentReference[oaicite:5]{index=5}

Inventory tactics

- Classify SKUs by criticality and lead time; keep higher safety stock on long-lead specialty grades.

- Use vendor-managed inventory (VMI) for high-velocity SKUs to smooth supply swings.

- Implement rolling 90- to 180-day forecasts tied to contractual pricing bands where feasible.

A simple cost-breakdown table (example)

| Component | Example % of landed unit cost |

| Raw material (coil/sheet) | 55% |

| Processing & stamping | 20% |

| Packaging, testing, QA | 5% |

| Freight & duties | 10% |

| Distributor margin & inventory cost | 10% |

Practical sourcing strategies

Buyers and suppliers that survived recent cycles typically combine several actions: contract indexation to raw-materials, multi-sourcing with regional partners, flexible order batching, and active freight management. For engineered washers or plated/treated parts, move to make-to-order where possible to avoid inventory obsolescence. For commodity washers, lock in price bands for 3–6 months while allowing quarterly renegotiations tied to nickel/scrap. Suppliers should publish simple lead-time and surcharge schedules to reduce disputes. :contentReference[oaicite:6]{index=6}

Conclusion: expect periodic volatility, manage with data

Global supply-chain shifts mean stainless-steel washer prices will continue to move with raw-material indices, logistics cost, and regional policy shifts. The most effective response is operational: better SKU segmentation, conditional contracts that transparently share raw-material risk, freight strategy, and active monitoring of nickel, ferrochrome and scrap markets.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)