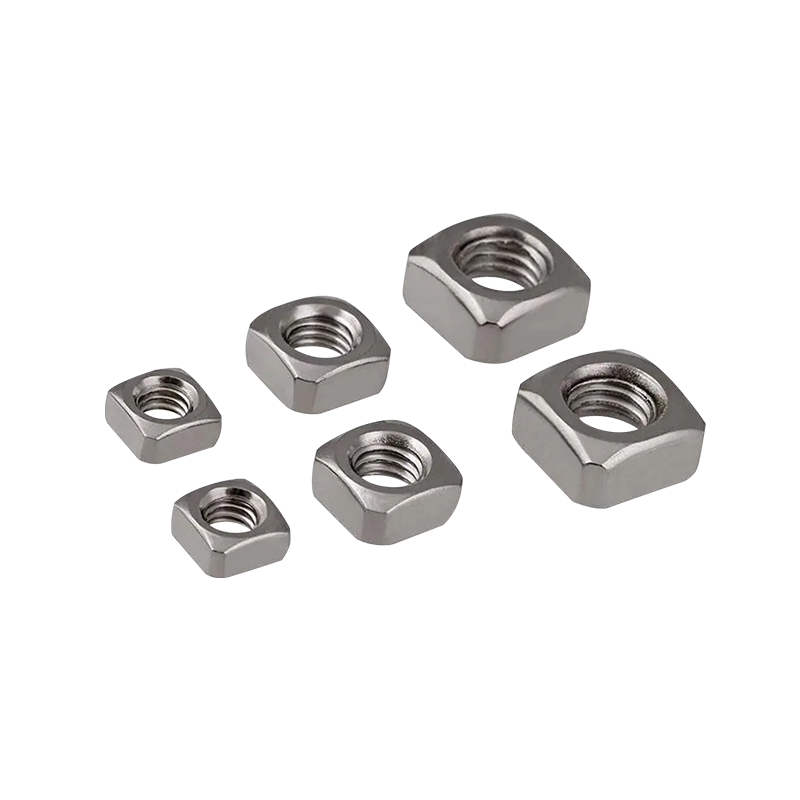

When it comes to fastening solutions, corrosion resistance is often one of the most critical factors to consider. This is especially true in industries and applications where fasteners are exposed to moisture, chemicals, or harsh outdoor environments. Stainless steel square nuts have earned a reputation for durability, strength, and reliability, with corrosion resistance being one of their standout features. But how exactly do they perform against rust and environmental degradation? Let’s explore their performance in detail.

1. Why Corrosion Resistance Matters

Corrosion occurs when metal reacts with oxygen, water, or other substances in the environment, leading to rust, weakening, and eventual failure of the component. For nuts and bolts, corrosion can be disastrous, as it compromises both safety and structural integrity. A rusted nut may seize up, making it impossible to loosen or tighten, and in extreme cases, it may even fracture.

Stainless steel square nuts are designed to combat this problem, making them a reliable choice for long-term use in challenging environments such as construction, marine, automotive, and outdoor installations.

2. The Role of Stainless Steel in Preventing Rust

The secret behind stainless steel’s corrosion resistance lies in its alloy composition. Stainless steel typically contains at least 10.5% chromium, which reacts with oxygen in the environment to form a very thin, invisible passive oxide layer on the surface. This protective film prevents further oxidation and acts as a self-healing barrier—if the surface is scratched, the layer regenerates in the presence of oxygen.

Depending on the grade of stainless steel used in the square nuts, the level of corrosion resistance can vary. For example:

304 stainless steel: Offers good corrosion resistance in general environments, suitable for indoor and mildly outdoor applications.

316 stainless steel: Contains molybdenum, which improves resistance against chlorides and saltwater, making it ideal for marine and coastal environments.

3. Performance in Different Environments

Stainless steel square nuts are versatile because they can withstand different levels of exposure:

Indoor applications: In dry, indoor environments, stainless steel nuts are highly durable and will remain free from corrosion for decades.

Outdoor environments: Exposure to rain, humidity, and fluctuating temperatures is well handled by 304 stainless steel, though long-term performance is better with higher grades like 316.

Marine and chemical industries: In environments where salt, acids, or chemicals are present, 316 stainless steel provides superior corrosion resistance, preventing pitting and crevice corrosion.

This makes stainless steel square nuts a go-to choice in industries that demand longevity and safety under tough conditions.

4. Comparison with Other Materials

It’s also important to compare stainless steel square nuts with alternatives:

Carbon steel nuts: While stronger in some applications, they are prone to rust unless coated or plated. Protective layers can wear off over time, leading to eventual corrosion.

Galvanized steel nuts: Zinc coatings provide temporary protection, but once scratched or worn, corrosion begins quickly.

Brass or bronze nuts: These offer decent resistance but are softer and less suitable for high-strength applications.

Stainless steel square nuts strike a balance, offering both mechanical strength and long-lasting corrosion resistance, which many other materials cannot provide simultaneously.

5. Maintenance and Longevity

One of the biggest advantages of stainless steel is its low-maintenance nature. Unlike plated or coated fasteners that require regular inspections and potential replacements, stainless steel nuts generally need only minimal care. Regular cleaning with mild soap and water can help maintain their appearance, but even without frequent maintenance, their protective passive layer ensures longevity.

In most cases, stainless steel square nuts can last for decades without significant signs of rust, making them cost-effective in the long run despite a higher upfront price.

6. Practical Applications

Thanks to their corrosion resistance, stainless steel square nuts are widely used in applications such as:

Outdoor furniture assembly

Wooden structure fastening

Marine equipment and docks

Chemical processing machinery

Automotive and aerospace components

Bridges, railings, and construction projects

In all these cases, the nuts must withstand not only mechanical loads but also environmental stress. Stainless steel ensures they remain secure and functional over time.

Conclusion

The corrosion resistance of stainless steel square nuts is one of their greatest strengths. By leveraging the natural protective oxide layer formed by chromium—and enhanced further with elements like molybdenum in higher grades—they deliver exceptional durability across a wide range of environments. Compared with carbon steel or coated fasteners, stainless steel provides longer service life, reduced maintenance needs, and greater reliability.

In short, whether you are using them for household projects, industrial applications, or marine construction, stainless steel square nuts offer an ideal combination of strength, longevity, and corrosion resistance. Investing in them ensures peace of mind, knowing that your fastening system will remain strong and rust-free for years to come.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)