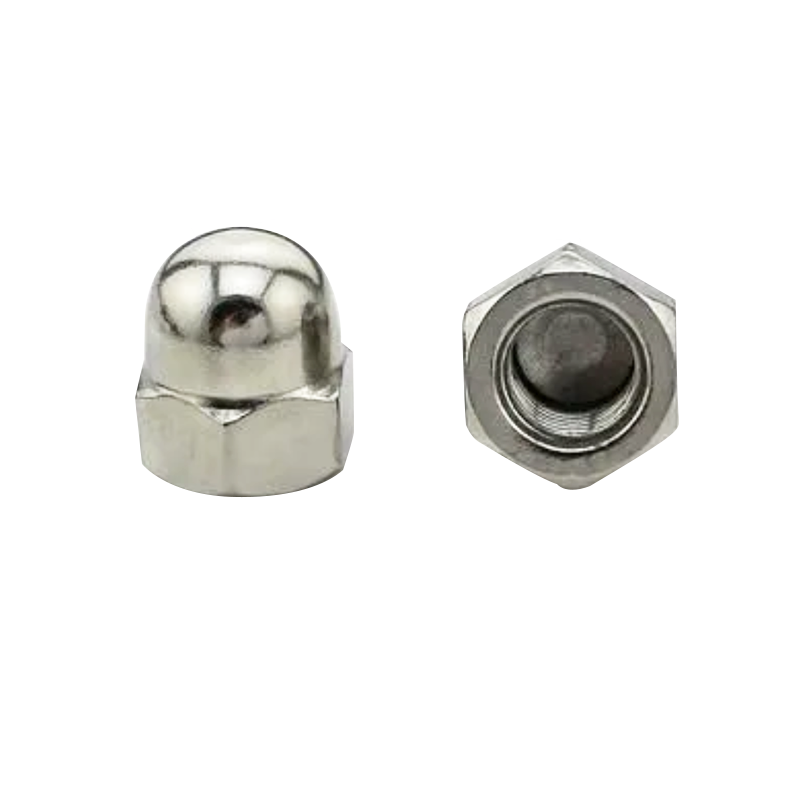

Stainless steel cap nuts, also known as acorn nuts or dome nuts, are a type of fastener designed with a closed-end dome shape. These nuts serve both practical and aesthetic purposes in a wide range of industries, from construction and automotive to furniture and machinery. Their unique shape and material offer added protection, durability, and a polished finish that traditional nuts may not provide. In this article, we will explore the primary functions and advantages of stainless steel cap nuts, explaining why they are commonly chosen for many applications.

1. Protecting Threaded Bolts

One of the core functions of a stainless steel cap nut is to cover and protect the exposed threaded end of a bolt or screw. Traditional nuts leave threads exposed, which can be vulnerable to:

Rust and corrosion

Physical damage from impact or friction

Accidental contact that may cause injury

By covering the threads completely, cap nuts reduce wear and tear, extend the lifespan of the bolt, and help maintain the integrity of the joint.

2. Preventing Injuries and Enhancing Safety

Exposed threads on bolts can be sharp or abrasive, posing a risk of injury to workers, operators, or anyone nearby. This is especially important in public areas, furniture, playgrounds, or machinery where safety is a top priority.

Stainless steel cap nuts eliminate this risk by enclosing the end of the bolt with a smooth, rounded surface. This makes them ideal for applications where user safety and accident prevention are essential.

3. Improving Aesthetic Appearance

Another key function of cap nuts is enhancing the appearance of an assembly. The polished dome-shaped design gives a clean and finished look to fastened joints. This is particularly important in industries where visual appeal matters, such as:

Architecture and decorative metalwork

Furniture manufacturing

Automotive detailing

Stainless steel handrails and fixtures

Stainless steel, with its natural luster and resistance to tarnishing, offers a sleek and modern look that fits well in both indoor and outdoor environments.

4. Corrosion Resistance in Harsh Environments

Stainless steel cap nuts are highly valued for their resistance to rust, corrosion, and oxidation. This makes them ideal for use in environments exposed to:

Water and moisture

Salt (e.g., marine applications)

Chemicals or industrial fumes

Extreme temperatures

Grades such as 304 and 316 stainless steel offer different levels of corrosion resistance, with 316 being more suitable for marine or chemically aggressive environments.

5. Securing and Locking Fasteners

While the main locking function is typically handled by the bolt and nut connection, cap nuts can also help secure the assembly by preventing loosening from vibration or movement. In some applications, they are paired with lock washers or thread-locking compounds for added stability.

In certain cases, cap nuts are used to discourage tampering or unauthorized disassembly, since the closed end can make it more difficult to access the bolt without the right tools.

6. Preventing Contamination and Debris Accumulation

In environments like food processing, medical equipment, and electronics, it's important to prevent debris, dust, or liquids from entering threaded holes or fasteners. The closed-end design of stainless steel cap nuts seals the bolt and helps prevent contaminants from accumulating in the threads.

This function supports cleanliness, hygiene, and system integrity, especially in sanitary or sterile environments.

7. Providing Electrical Insulation (with Modifications)

Although stainless steel itself is conductive, in some specialized applications, cap nuts may be coated or combined with insulating washers to provide electrical isolation. This is useful in electronics, telecommunications, and control panels where components must be kept separate to avoid short circuits or interference.

8. Vibration and Shock Resistance

In automotive, railway, and machinery applications, fasteners are subjected to constant vibration and dynamic forces. Cap nuts help maintain the tightness and stability of bolted joints, especially when used with spring washers or nyloc inserts. Their enclosed design reduces the chances of loosening due to motion, improving mechanical reliability.

9. Customization and Versatility

Stainless steel cap nuts come in various shapes, thread sizes, and surface finishes. They can be hex-shaped, round, or custom-designed to fit different applications. This versatility allows engineers and designers to adapt cap nuts to both standard and highly specialized uses.

They are also available in metric and imperial measurements, making them suitable for global use and compatible with a wide range of bolts.

Stainless steel cap nuts are not just about good looks—they are multifunctional fasteners that protect, secure, and enhance the safety and longevity of bolted assemblies. Their dome-shaped design protects threads, prevents injuries, and improves aesthetics, while the stainless steel construction ensures corrosion resistance and durability in challenging environments. From industrial machinery and construction to decorative furniture and marine equipment, stainless steel cap nuts offer reliable performance and a professional finish in any application.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)