Introduction to Hexagon Flange Nuts

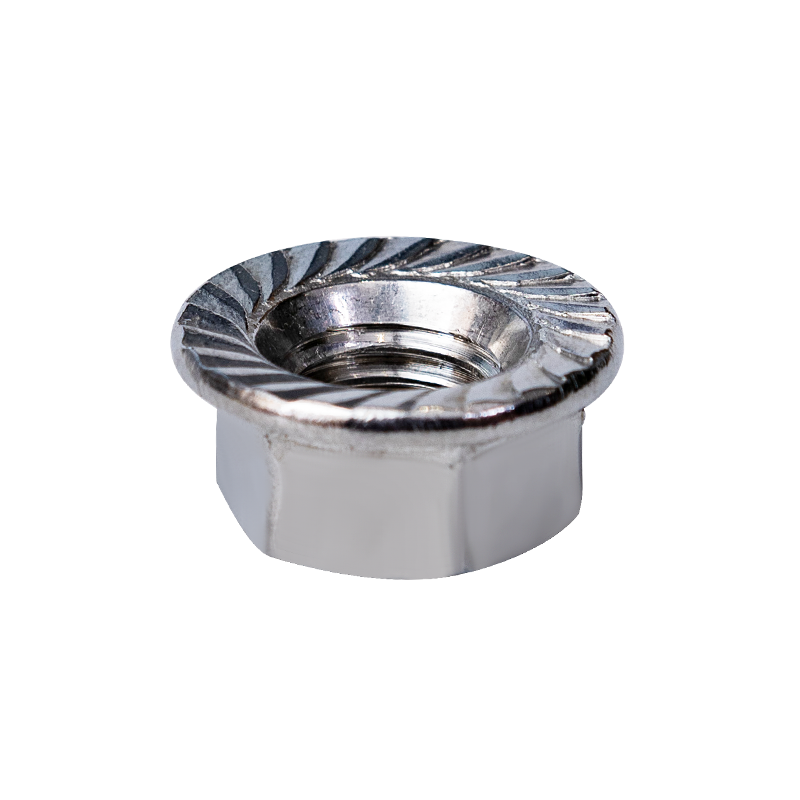

Hexagon flange nuts are specialized fasteners used extensively in mechanical assemblies. Distinguished by their hexagonal shape and integrated flange, they provide superior load distribution, improved resistance to loosening, and reduced need for washers. Modern industries increasingly rely on these nuts to enhance assembly efficiency, ensure mechanical safety, and maintain structural integrity under heavy or dynamic loads.

Unlike standard hex nuts, flange nuts integrate a broad base or flange that acts like a built-in washer. This feature increases the surface area that contacts the material, reducing stress concentration and minimizing damage to connected components. Their design makes them particularly valuable in automotive, machinery, and construction applications where reliability is critical.

Design Advantages of Hexagon Flange Nuts

Hexagon flange nuts combine simple geometry with practical engineering advantages. The hexagonal shape allows for easy tightening using standard wrenches or sockets, while the integrated flange distributes load evenly across the contact surface. This prevents deformation, reduces vibration-induced loosening, and ensures stronger joints.

Key design advantages include:

- Enhanced load distribution for improved structural stability.

- Integrated flange reduces the need for separate washers, simplifying assembly.

- Hexagonal shape enables easy torque application and adjustment.

- Compatibility with standard fastener tools for rapid installation.

Material Selection and Performance

Material selection plays a critical role in the performance of hexagon flange nuts. Common materials include carbon steel, stainless steel, and alloy steel. Each material provides specific benefits depending on the mechanical and environmental demands of the application.

For example, stainless steel nuts offer corrosion resistance for outdoor or humid environments, while high-strength alloy steels are ideal for high-load machinery. Heat treatment, surface coatings, and galvanization further enhance durability, wear resistance, and longevity.

Applications in Mechanical Assembly

Hexagon flange nuts are widely used across industries due to their versatility. They provide reliable fastening in situations where vibration, thermal expansion, or heavy load conditions may compromise standard nuts. Common applications include:

- Automotive assembly, including engines, chassis, and suspension systems.

- Industrial machinery, ensuring stability in rotating and vibrating equipment.

- Construction, particularly steel framework and heavy-duty structures.

- Electronics and appliances, where uniform load distribution prevents component damage.

By integrating hexagon flange nuts, engineers can achieve faster assembly times, reduce component failures, and ensure consistent torque application.

Comparing Hexagon Flange Nuts with Standard Nuts

The key difference between hexagon flange nuts and standard hex nuts lies in the built-in flange. While standard nuts often require washers to distribute load and prevent loosening, flange nuts achieve this inherently. The table below highlights performance differences:

| Feature | Standard Hex Nut | Hexagon Flange Nut |

| Load Distribution | Requires washer | Integrated flange |

| Resistance to Loosening | Medium | High |

| Ease of Installation | Medium | Fast and reliable |

| Surface Protection | Requires separate washer | Flange prevents damage |

| Vibration Resistance | Low | High |

Installation Techniques and Best Practices

Proper installation of hexagon flange nuts is essential to maximize their benefits. Applying the correct torque prevents over-tightening or loosening under vibration. Tools such as calibrated torque wrenches are recommended for critical applications.

Additional best practices include:

- Ensuring the flange surface is clean and free from debris.

- Using thread-locking compounds for high-vibration environments.

- Regular inspection to detect wear or deformation in critical assemblies.

- Selecting materials compatible with environmental conditions to prevent corrosion.

Advantages for Industrial Productivity

By reducing assembly time, minimizing loosening, and distributing loads evenly, hexagon flange nuts improve overall industrial productivity. Assembly lines benefit from fewer stoppages and reduced need for additional components such as washers, lowering costs and simplifying inventory management.

Engineers also report improved reliability in machinery operation due to consistent torque and reduced stress concentration, extending the lifespan of components and reducing maintenance downtime.

Material Coatings and Corrosion Resistance

Surface coatings enhance performance and longevity. Hexagon flange nuts often feature zinc plating, galvanization, or black oxide coatings to resist corrosion, especially in outdoor or humid environments. Stainless steel variants provide inherent corrosion resistance without additional coatings.

Selecting the appropriate coating or material ensures long-term performance in specific industrial settings and reduces the risk of joint failure due to environmental exposure.

Conclusion: Essential Components for Modern Assembly

Hexagon flange nuts play a crucial role in modern mechanical assembly by providing strong, reliable fastening solutions that combine ease of installation, vibration resistance, and load distribution. Their integrated flange eliminates the need for separate washers while enhancing structural integrity, safety, and efficiency.

By selecting the correct material, torque, and installation practices, manufacturers and engineers can leverage hexagon flange nuts to improve productivity, reduce maintenance, and ensure consistent assembly quality across diverse industrial applications.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)