Understanding High-Load Connections and Joint Behavior

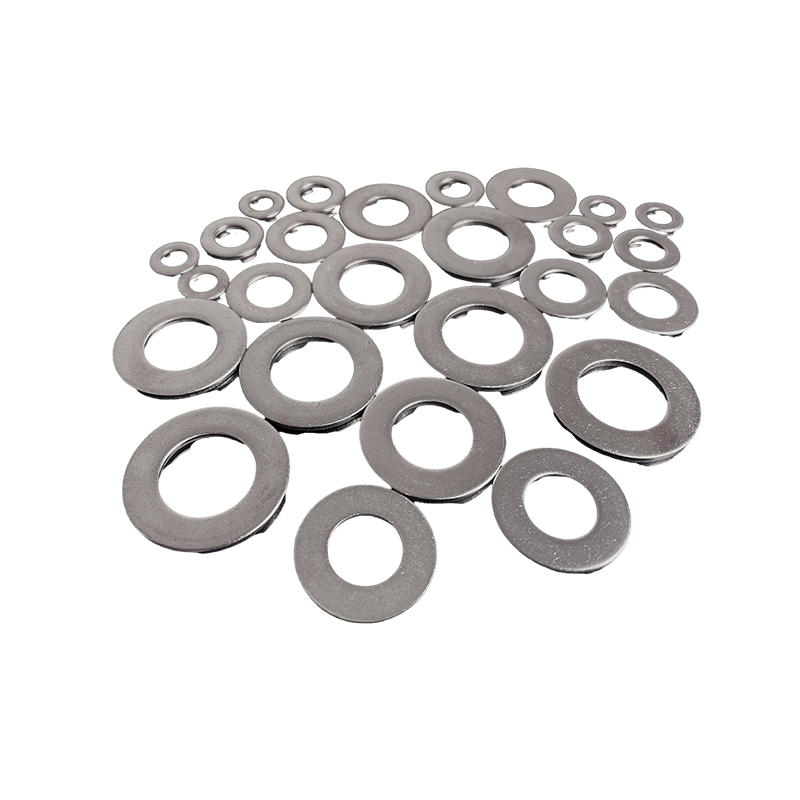

High-load connections are mechanical joints where fasteners are subjected to significant static or dynamic forces. These loads may arise from structural weight, vibration, thermal expansion, or cyclic stress during operation. In such environments, the performance of a bolted joint depends not only on the bolt and nut but also on how the load is transferred to the connected surfaces. Flat washers play a critical role in managing these forces by influencing stress distribution, surface protection, and long-term joint stability.

Without proper load management, high-load connections are prone to localized deformation, embedment loss, or uneven clamping pressure. These issues can gradually reduce preload and compromise joint integrity. Flat washers are often introduced as a simple yet effective component to address these challenges, but their use must be based on specific mechanical conditions rather than habit or convention.

How Flat Washers Influence Load Distribution

One of the primary reasons to use flat washers in high-load connections is their ability to distribute compressive forces over a larger surface area. When a nut or bolt head is tightened directly against a joint surface, the contact area is relatively small, resulting in high contact stress. In high-load applications, this concentrated stress can exceed the bearing strength of the material, leading to surface indentation or creep.

Flat washers increase the effective bearing area, reducing surface pressure and helping maintain consistent clamping force. This is particularly important when connecting softer materials such as aluminum, copper alloys, or coated steel components, where surface deformation can occur even under moderate preload.

Load Spreading Benefits

- Reduces localized surface stress under bolt heads and nuts.

- Minimizes permanent deformation in softer joint materials.

- Improves consistency of preload across multiple fasteners.

- Supports predictable torque-to-tension relationships.

Situations Where Flat Washers Are Mechanically Necessary

Flat washers should be used in high-load connections when the joint design presents conditions that increase the risk of surface damage or preload loss. These conditions are often related to material properties, joint geometry, or loading characteristics rather than load magnitude alone. Engineers must evaluate how the applied force interacts with the joint interface.

For example, when the bearing surface under the bolt head is uneven, slotted, or oversized, direct contact can lead to uneven stress concentration. A flat washer provides a stable and uniform contact surface, allowing the fastener to seat properly and maintain alignment under load.

Common High-Load Scenarios Requiring Flat Washers

- Connections involving soft or layered materials.

- Structural joints with oversized or slotted holes.

- Assemblies exposed to vibration or cyclic loading.

- High-preload bolted joints requiring torque accuracy.

- Interfaces with protective coatings or surface treatments.

Flat Washers and Preload Retention

In high-load connections, maintaining preload over time is often more critical than achieving a high initial tightening force. Preload loss can occur due to embedment relaxation, where microscopic surface irregularities flatten under load. Flat washers help mitigate this effect by providing a smoother, more uniform bearing surface that reduces the rate of embedment.

This function is particularly important in joints subjected to fluctuating loads, where even small reductions in preload can allow micro-movement between components. Over time, such movement accelerates wear and increases the risk of fatigue failure in both the fastener and the connected parts.

Material Compatibility in High-Load Washer Selection

Not all flat washers are suitable for high-load connections. The washer material must be compatible with both the fastener and the joint material to ensure balanced load transfer. Using a washer that is too soft may result in excessive deformation, while a washer that is too hard may concentrate stress at its edges.

In high-load steel-to-steel connections, hardened flat washers are often preferred to maintain shape under compression. For mixed-material joints, washer selection must consider galvanic compatibility, corrosion resistance, and surface hardness.

Typical Washer Materials and Use Cases

| Washer Material | Suitable High-Load Application |

| Hardened Carbon Steel | Structural steel joints |

| Stainless Steel | Corrosion-prone environments |

| Alloy Steel | High-preload machinery joints |

Flat Washers in Dynamic and Fatigue-Prone Connections

High-load connections often operate under dynamic conditions, where vibration and cyclic forces are present. In these cases, flat washers contribute indirectly to fatigue resistance by stabilizing contact surfaces and reducing uneven stress transfer. While they do not prevent loosening on their own, they support other retention methods by maintaining uniform contact pressure.

In applications such as heavy machinery, transport equipment, or structural frameworks, flat washers help preserve joint geometry under repeated load cycles. This consistency reduces bending stress in bolts, which is a common cause of fatigue-related failures.

When Flat Washers May Be Unnecessary

Despite their advantages, flat washers are not required in every high-load connection. Some modern fasteners are designed with integrated flanges that already provide sufficient bearing area. In precision-machined joints with hardened contact surfaces, additional washers may offer limited benefit and could even alter preload calculations.

The decision to use flat washers should therefore be based on joint analysis rather than generalized rules. Evaluating surface hardness, contact area, and load path is essential to determine whether a washer contributes meaningful performance improvements.

Practical Guidelines for Engineering Decisions

In high-load connections, flat washers should be selected and applied as part of an integrated joint design strategy. Engineers must consider how the washer interacts with fasteners, joint materials, and operating conditions over the full service life of the assembly. Proper use can enhance reliability, while improper selection can introduce new failure modes.

By focusing on load distribution, preload retention, and material compatibility, flat washers become a practical tool for improving joint performance rather than a default accessory. Their value lies not in their simplicity, but in their correct application within high-load mechanical systems.

русский

русский Español

Español عربى

عربى italiano

italiano

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province

No. 2 Bridge, Chuangxin Road, Dainan Town, Xinghua City, Taizhou City, Jiangsu Province  +86-17315333748(Wechat)

+86-17315333748(Wechat)

+86-17315333748(Wechat/Whatsapp)

+86-17315333748(Wechat/Whatsapp)